In detailing, the recommended method for applying most waxes and coatings is known as the criss-cross method. What exactly does it mean? What movements should you use when applying wax? Should it be used always and every time? We answer these questions!

Often compared with less efficient circular motions or labour-intensive application using a polishing machine, criss-cross application has become a standard in guides and product instructions in the detailing world. It is both a simple and clever application method that anyone can master.

What is criss-cross application in car care?

In automotive cosmetics, criss-cross application is considered the most efficient and practical way of transferring a chemical product (wax, ceramic coating, glass coating, etc.) onto the surface of a vehicle. What makes criss-cross movements superior?

Main advantages of criss-cross application of waxes and coatings:

- It is the most reliable way to achieve even surface coverage

- You don’t move the applicator over the same spot more than once

- You avoid leaving small unprotected gaps, which often happens with circular motions

- The method allows you to focus on what is “within arm’s reach”

These aspects are the key benefits of the criss-cross method, but of course we must not forget about the need for careful and precise movements. The method itself won’t do the job for us!

How to apply car wax using the criss-cross method?

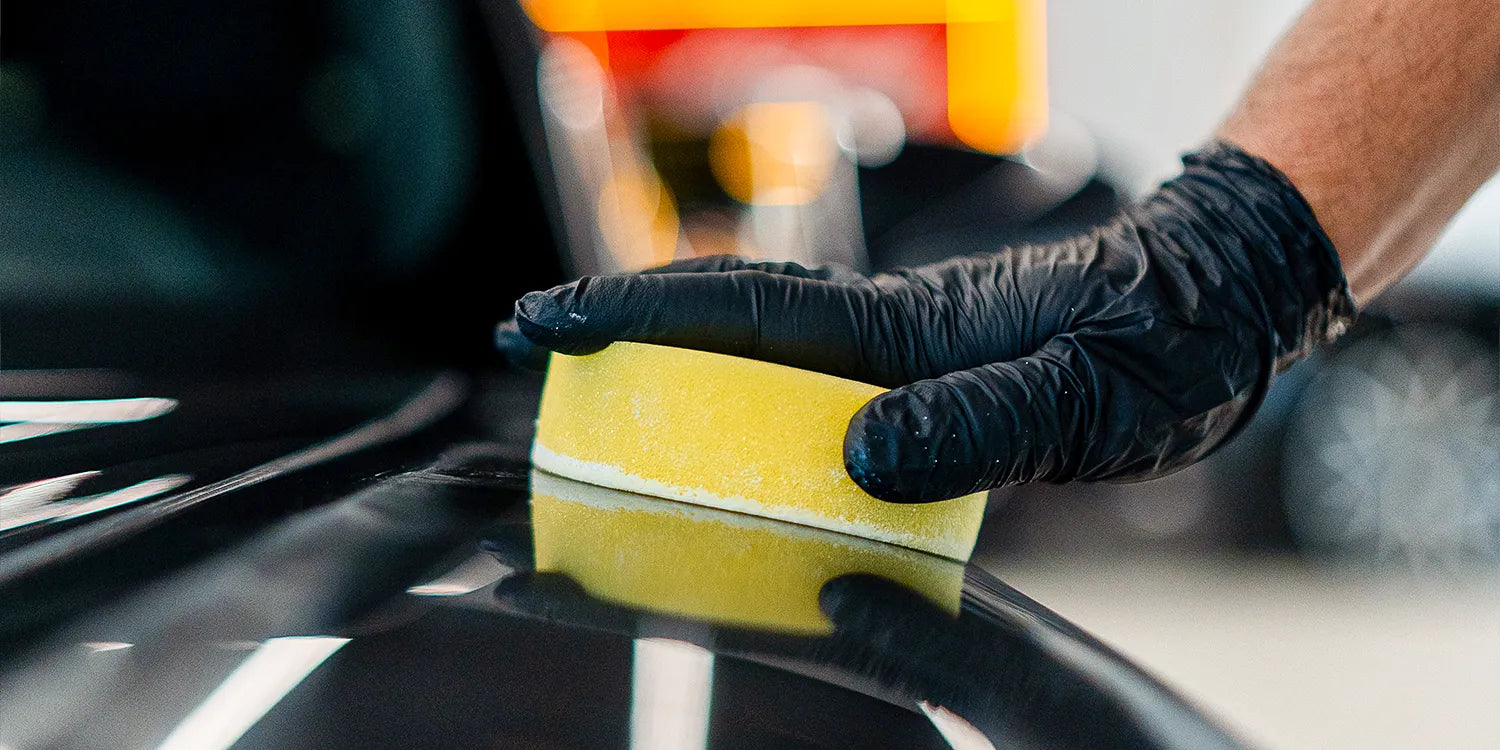

In our main category of car waxes, each product comes with the characteristic yellow foam applicator. There are minor exceptions to this rule (such as the uniquely shaped applicator in Authentic Premium or microfibre cloths instead of sponges in Mirror Shine or Scratch Clear), but the yellow sponge should be well known to all Soft99 wax fans.

Before starting, pay attention to any special instructions that accompany certain waxes. For example, with the bestselling Fusso Coat 12 Months, we recommend slightly moistening the applicator before use (for instance by dipping it in water and squeezing out the excess).

Criss-cross wax application step by step:

Let’s begin by opening the tin. Remove the plastic lid, making sure the foam applicator doesn’t fall to the floor, then use the lid to pry open the metal cover underneath. The characteristic metallic “clang” lets you know the wax is open. Interestingly, you can easily re-seal it by pressing the metal lid firmly back into place.

Hold the applicator so that you can easily press it against the wax surface. Rotate it 3-4 times inside the tin. This is enough product to cover a medium-sized body panel, such as one-third of the hood. Pay attention to the consistency of the wax – for example, White Soft99 Wax is our softest wax, so be careful not to pick up too much.

Mentally divide the panel you are working on into smaller sections. This will help you focus on precise application and avoid rushing.

Place the applicator in the corner of the chosen area and start applying the wax by moving the applicator in one direction, for example horizontally. When you reach as far as your arm allows, lower the applicator slightly and begin “painting” a second line of wax, making sure not to leave any gaps.

Once you have covered the entire section with horizontal lines, repeat the process in the vertical direction. Your movements should cross at a right angle to the first phase of application – this is where the method gets its name.

Your movements should follow the pattern shown in the illustration. The first phase (horizontal movements) is marked in white, and the second phase (vertical movements) is marked in yellow. The exact direction (up/down) or starting point (left/right or top/bottom corner) can be chosen freely depending on which side of the car you are working on and which hand you are using.

That’s it! This way you minimise the risk of missing small areas and distribute the wax more effectively.

Criss-cross application is not always necessary

Should we stick to criss-cross application everywhere and every time? Not necessarily.

Soft99 waxes that come with a microfibre cloth – Scratch Clear and Mirror Shine – are products in which the wax bonding stage has been eliminated. This means that these waxes should simply be buffed into the paint in a single step until full gloss is achieved. In such cases, circular motions can be used, as they are more natural when working with microfibre.

Finally, remember that the key to successful criss-cross application lies in adapting your movements to the shape of the element you are working on. You will need a different approach (number of strokes, how many segments to divide the area into, etc.) for a complex, curved spoiler than for a simple mirror housing. Like any application method, this one also requires practice and experience, so don’t be discouraged if your first attempt isn’t perfect. Good luck!

Europe | €

Europe | €

Deutschland | €

Deutschland | €

Polska | zł

Polska | zł